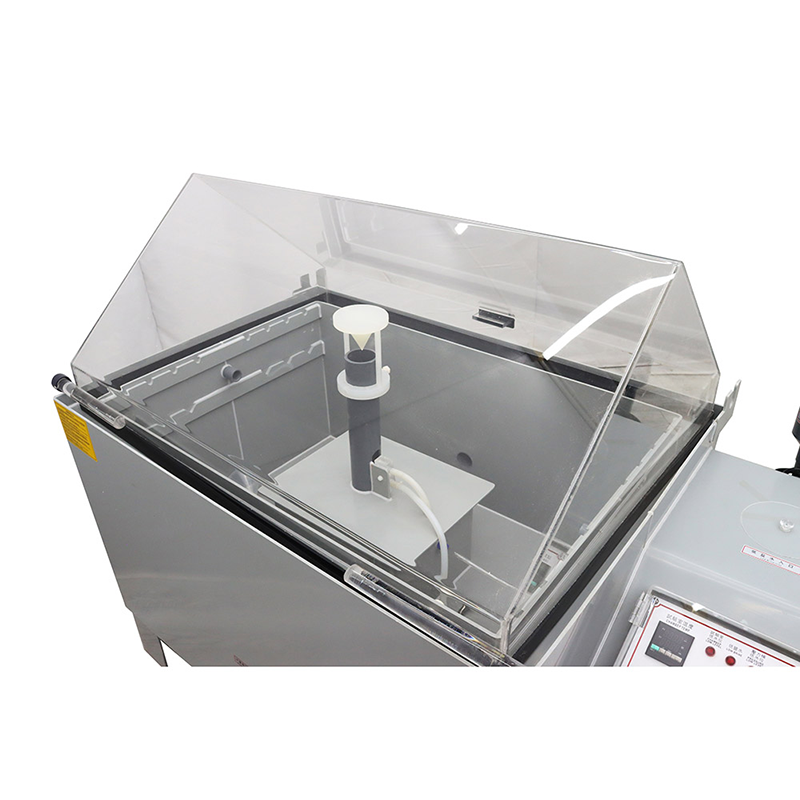

JK-90C, 900*600*400 Enhanced Version, Recyclable Spray

Salt spray testing chamber 110V. This product is used to test the corrosion resistance of the electrodeposited coating of many kinds of metallic materials.Use the salt spray test machine to spray the Sodium Chloride Solution to the surface of electric coating to achieve the purpose of detection.Best to calibrate the concentration once a day.Test the PH value during experience after collection.Continuously, cannot interrupt.Collect once per hour, at least 16 hours, mean the average value.Test at least twice a day, interval seven hours every time.Other humidity required by the seller and the buyer agreement.Continuous time from the beginning to the end.

1. Product parameter:

Voltage: 110V

Power:2000W

Laboratory volume: 270L

Inner size: 35.4*23.6*15.7 inch (900*600*400mm)

Outer size: 54.7*28.7*43.3inch (1390*730*1100mm)

Spray method: continuous

2. Product display:

3. Product information:

-----Blunt material is required, it is required that the material itself cannot be corroded, and it can not affect the corrosion test.

-----The fog nozzle cannot spray the test liquid directly to the sample , the solution at the top of the spraying chamber cannot drop on the test piece.

-----The test liquid dropped from test piece cannot flow back to the salt bucket again for the test.

-----The solution should not contain grease and dust, so you have to prepare an air cleaner.

-----The level area of the spray taking device is 80 cm2, the diameter is about 10 cm. Put the spray taking device beside the test piece.

-----Spray liquid should be collected at least 16 hours, an average per hour can be collected 2ml to 1ml solution. Use the final average to represent the amount of spray.

-----The concentration of the Sodium Chloride Solution should be maintained at 40~60g/L.

-----The temperature of the pressure barrel should be kept in 47+1 degree, temperature of the brine barrel should be kept in 35+1 degree.

-----The machine have timing function, and you could set time to open or close automatically.

4. Product dimensions:

5. Scope of application:

This product is used to test the corrosion resistance of the electrodeposited coating of many kinds of metallic materials.

6. Precautions:

-----Use the salt spray test machine to spray the Sodium Chloride Solution to the surface of electric coating to achieve the purpose of detection.

-----Best to calibrate the concentration once a day.

-----Test the PH value during experience after collection.

-----Continuously, cannot interrupt.

-----Collect once per hour, at least 16 hours, mean the average value.

-----Test at least twice a day, interval seven hours every time.

-----Other humidity required by the seller and the buyer agreement.

-----Continuous time from the beginning to the end.