JK-60B 600*450*400 Enhanced Model

Salt Spray Testing Chamber 110V. Salt water spray testing machine is for various materials surface treatment, including coating, electroplating, organic and inorganic skin film, anodic treatment, anti-rust oil and other anti-corrosion treatment to test its corrosion resistance, so as to establish the quality of products.

1. Product parameter:

Voltage: 110V

Power: 2000W

Laboratory volume: 110L

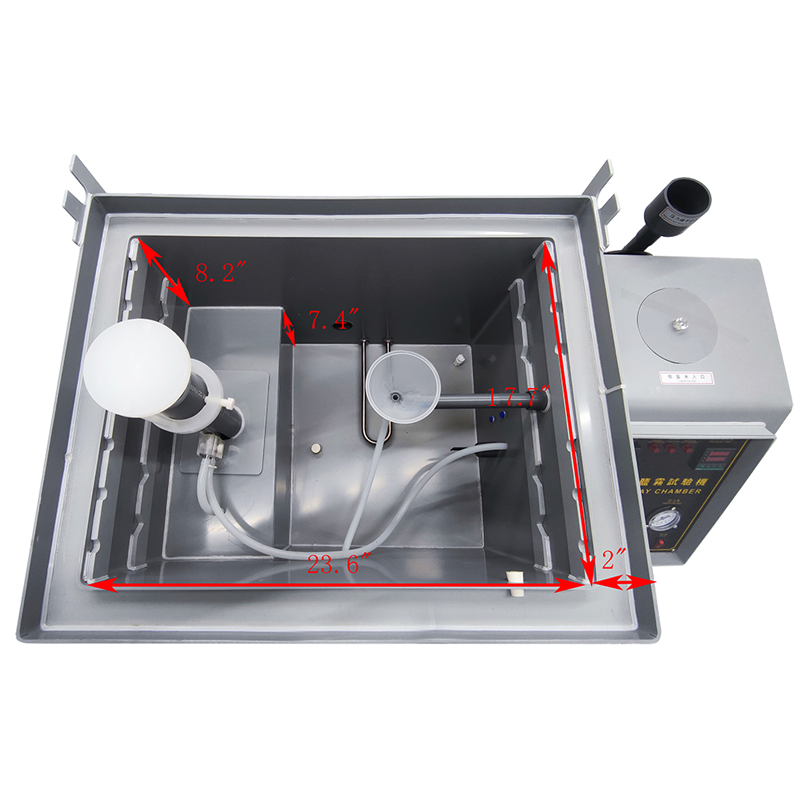

Inner size: 23.6*17.7*15.7 inch (600*450*400mm)

Outer size: 40.5*22.4*38.5 inch (1030*570*980mm)

Spray method: continuous

2. Product display:

3. Product Features:

-----All equipment needed in the test: Spray nozzle, salt water barrel, test piece support, spray liquid collection container, test chamber, salt water, supply tank, pressure tank, supply equipment and exhaust equipment required for compressed air, the device is shown in the figure, and the test is conducted as follow.

-----Blunt material is required, it is required that the material itself cannot be corroded, and it can not affect the corrosion test.

-----The fog nozzle cannot spray the test liquid directly to the sample , the solution at the top of the spraying chamber cannot drop on the test piece.

-----The test liquid dropping from test piece cannot flow back to the salt bucket again for the test.

-----The solution should not contain grease and dust, so you have to prepare an air cleaner.

-----The level area of the spray taking device is 80 cm2, the diameter is about 10 cm. Put the spray taking device beside the test piece.

-----Spray liquid should be collected for at least 16 hours, and the average of the solution collected in one hour is 1-2ml. Use the final average to represent the amount of spray.

-----The concentration of the Sodium Chloride Solution should be maintained at 40~60g/L.

-----The temperature of the pressure barrel should be kept in 47+1 DEG C, temperature of the salt water barrel should be kept in 35+1 DEG C.

4. Product dimensions: